Annual General Meeting 2015

Keen to start planning for the 2016 competition tour, we held our AGM early this year. The AGM took place on October 3rd 2015 at the Boars Head Hotel, Sudbury Derbyshire.

A new committee was duly elected and actions agreed to expedite several matters which included updating our constitution, rules and our great new website http://imacuk.org I referred to this in my last contribution but make no apology for mentioning it again. In addition to the resources section open to non members, particular attention has been given to making the website more user friendly, including of course to pilots who may be interested in joining IMAC.

You may remember that at our AGM last year, to enable pilots to compete in IMAC using the planes they usually fly at their local club, it was decided to relax the rules governing the type of plane that can be used to compete in Basic class. This was not as successful as we had hoped, in fact only a few pilots competed in Basic in 2015. Considering this and members’ wish to reduce the number of classes flown at competitions and increase the number of rounds flown, it was decided that there will no longer be a Basic class.

A special announcement it’s pleasing to highlight here is that Mick and Win Bull were awarded honorary membership at the AGM for their tireless and dedicated contribution to IMAC over many years. Congratulations again Mick and Win!

Mick and Win Bull at Castle Kennedy, Stranraer.

How Far Do You Go……?

With winter on us, and the opportunity for planned preventive maintenance (PPM) I think it’s a good time to review some technical issues and share a little information which will I hope benefit other pilots, whatever planes they fly.

In my observation, IMAC Pilots tend to be obsessional people, a characteristic not exclusive to IMAC but certainly the norm. My view is based not only on the intricate care given by IMAC pilots to their aeroplanes but also the considerable time and attention given to training practice and thorough planning and preparation for competitions. Nevertheless despite this pilots occasionally experience engine start failure, unreliability or other problems. To what extent can PPM improve reliability and above all, standards of safety? How far do you go with PPM?

Components such as carburettor pump diaphragm, petal reed valve, spark plug, RX or flight battery, servos and their connections, ball-links, clevis couplings, are only some parts eligible for periodic replacement but what attention should we give to these and other components, and how often?

A few examples:

Carburettor diaphragms and petal reed valves.

There seems to be a variety of opinion on when to change these parts. I’m not aware of specific guidelines but know I’m not alone in replacing carburettor diaphragms on my DA motors every year or second year, latest. Based on the experience of other IMAC pilots, it seems a first indication that reed petal valves need replacement is difficulty in starting the motor so perhaps routinely inspecting these parts could help prevent engine failure at the field.

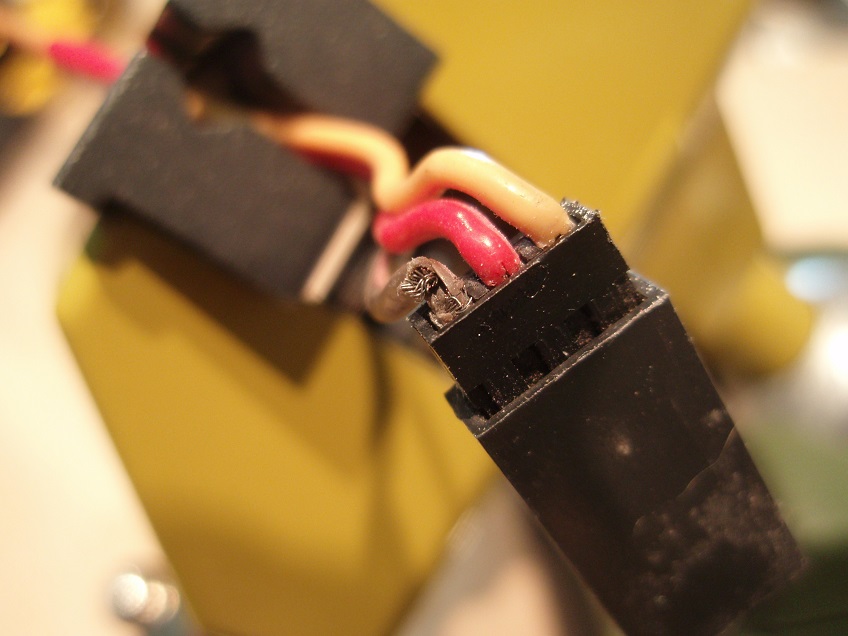

Broken reed valve, experienced at Cashmoor competition

Servo leads & connectors.

Some time ago, when at the flying field fitting the stabilisers to one of my planes I noticed that a lead to one of the connectors looked in poor condition. On close inspection I found all but one of the strands in the negative lead were broken. I was just “one strand away” from complete loss of elevator control with potential disastrous consequence I doubt I’d ever have found the cause. Needless to say, no flying that day. Back in the workshop I found that both elevator connection leads were fraying so replaced these with 6 pin Multiplex plugs and sockets. These are quick to connect especially where there are two servos per wing and have proved very robust and reliable. I’ve fitted this type of connector to all my planes and used these ever since. (As an added safety measure I always fit these plugs with Powerbox safety clips.)

Broken wires in servo lead

MPX connector for 2 servos with safety clip

I once bought cheaply priced “MPX Type” connectors. It was only when I was soldering the leads to the pins I noticed that the plug body did not have “MPX” embossed in the moulding. Viewed under a magnifying glass, the cheap plug and socket bodies were of doubtful quality so I disposed of the lot and fitted genuine MPX connectors throughout.

Silencers; what can go wrong……

Silencer canisters, or tuned pipe mounting and integrity of teflon connectors to exhaust manifolds are relatively easy to inspect. However a couple of years ago my trusty DA 150 failed to reach full revs. With the help of five others pilots I tried everything possible; changed carburettor, ignition, fuel line, tank; without success. Thinking I may have damaged the crankshaft on a poor landing a week earlier resulting in a “nose over” I sent the engine back to Tony Clarke in Germany for bench test. Result; no damage, the engine ran perfectly. I then remembered a suggestion made by Alan Griffiths that he had known silencer baffles to eventually break and come adrift. So I removed the silencer cans and sure enough baffles had broken off.

Canister silencer with broken baffles.

The amount of carbon deposit inside the cans, left me wondering if the holes had become blocked causing undue pressure on the baffles which eventually fatigued. I’ve now changed from the well known make of garden tool oil I had been using to Redline which burns very cleanly and have used it ever since with much cleaner result.

The propeller……

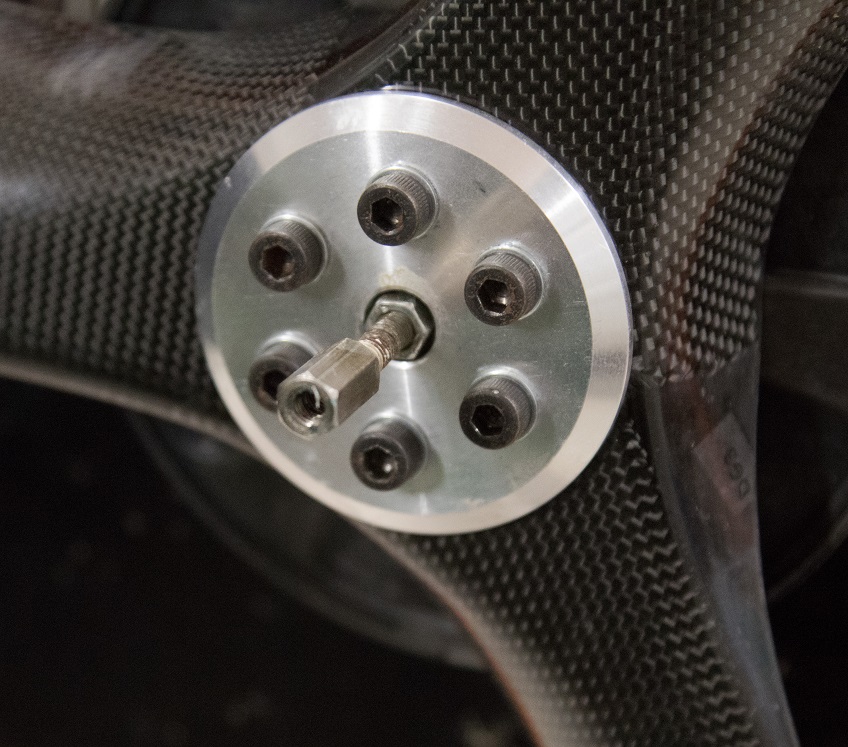

Typical Carbon Propeller on DA 200

In IMAC competition flying, we use carbon fibre propellers, to my knowledge, without exception. As a Desert Aircraft (DA) engine user I’ve always been careful to tighten prop bolts properly and check them periodically, especially after test flying a new plane. However after reading Manny Williamson’s article in issue 132 of “Chacksfield Chat” about the accident and serious injury that occurred when an aircraft shed its propellor I checked the precise instructions given by DA. The company stresses the importance of periodically checking the tightness of the M5x55mm steel propeller bolts. For the DA 200 for example, DA specify that when using a carbon propeller, the bolts must be tightened to a torque of 90 in.lb. = 10.2 Nm. I now always use a torque wrench set to 10.2 Nm to tighten the prop bolts and check they’re tight regularly. In issue 133 Manny referred again to the accident; including reference to the advisability of checking prop bolt torque settings which I re-iterate in view of its importance.

Spinner removed, showing propeller retaining bolts.

Note: I’m advised by the European Agent for DA, Tony Clarke in Germany, that it’s important to ensure when replacing the bolts replacement bolts are of exactly the same type and quality as those supplied by the manufacturer.

So how far you go with maintenance is a matter of personal choice. I hope the above is food for thought and of some value.

Looking ahead; Competition Season 2016

As mentioned in the last edition of BMFA News, our first event in 2016 is the "Introduction to IMAC" weekend on April 16 & 17th. The weekend is open to all pilots holding at least a BMFA "A" certificate. The structure is informal and will include both demonstration flights and coaching intended to get you flying the aerobatic schedules using your own plane. As always there will be a warm and friendly welcome from our regular pilots and the host club Langar MAC. For more event details go to our website http://imacuk.org and click on "Introduction to IMAC Weekend" on the left-hand side.

We would like to thank Langar MAC (http://langarmac.co.uk) for allowing us to use their facilities for this event which include provision for overnight camping and permanent toilets.

We look forward to seeing you there.